PVC Ceiling panel production machine

It’s used to produce PVC ceiling wall panel with different size, such as 200mm, 250m,300mm, 400mm, 600mm and so on.

Production flow of PVC ceiling panel manufacturing equipment :

Material batching mixing-extruding-molding-vacuum calibrating and cooling-hauling-cutting- final PVC ceiling

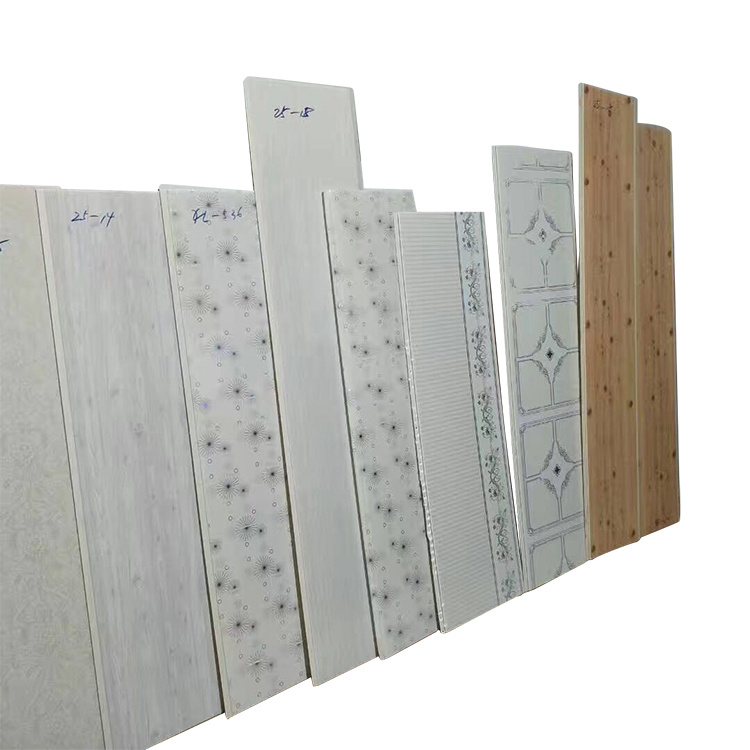

Surface treating ways:

- hot stamp printing

- two color printing

- lamination

The main machines needed for PVC ceiling wall panel:

-PVC mixer

-PVC panel extrusion line

(Including autoloader, conical twin screw extruder, mould, vacuum calibration chamber, hauling machine, auto cutter- stacker)

- hot stamp printer or two color printing line or lamation

- PVC crusher& PVC miller

- Air compressor

- Water chiller (optional)

Main technical parameters of PVC Ceiling panel production machine:

| Popular Model | YF-300 | YF-600 |

| Extruder | SJZ51/105 | SJZ65/132 |

| suitable size of panel | 160mm,200mm,250mm,300mm | 250mm,300mm,400mm,600mm |

| Max capacity(kg/h) | about 100 | about 200 |

| production line speed | 3.5-5m/min | |