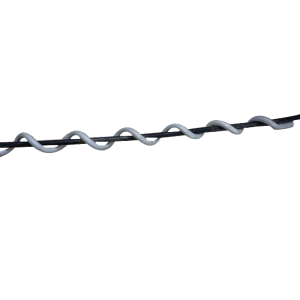

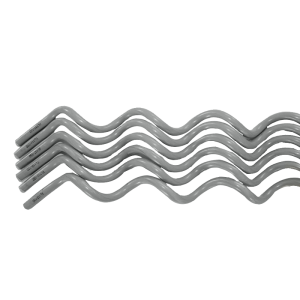

High voltage spiral vibration damper making machine

The extruded product is coded by a laser inkjet printer, shaped by forming mold, The forming mold is designed and processed according to customer requirements.

Main Features of High voltage spiral vibration damper making machine / PVC Tie making machine:

1)Extruder screw and barrel are all good quality alloy steel 38CrMoVAlA from Zhoushan,with nitriding treatment and surface special

treatment,good quality with long life time.

2) Gearbox: Chinese famous brand,hard teeth helical gear reducer,with nice outline, stable running, low noise and long service

time.

3) Heating system: adopting cast aluminum heaters with #304 stainless steel plate covers, wind separate fan cooling system,

ensuring good features of cooling and heating, precision temperature controlling.

4) Driving system: adopting famous brand Siemens motor, using ABB inverter which provide stable torque output and various speed.