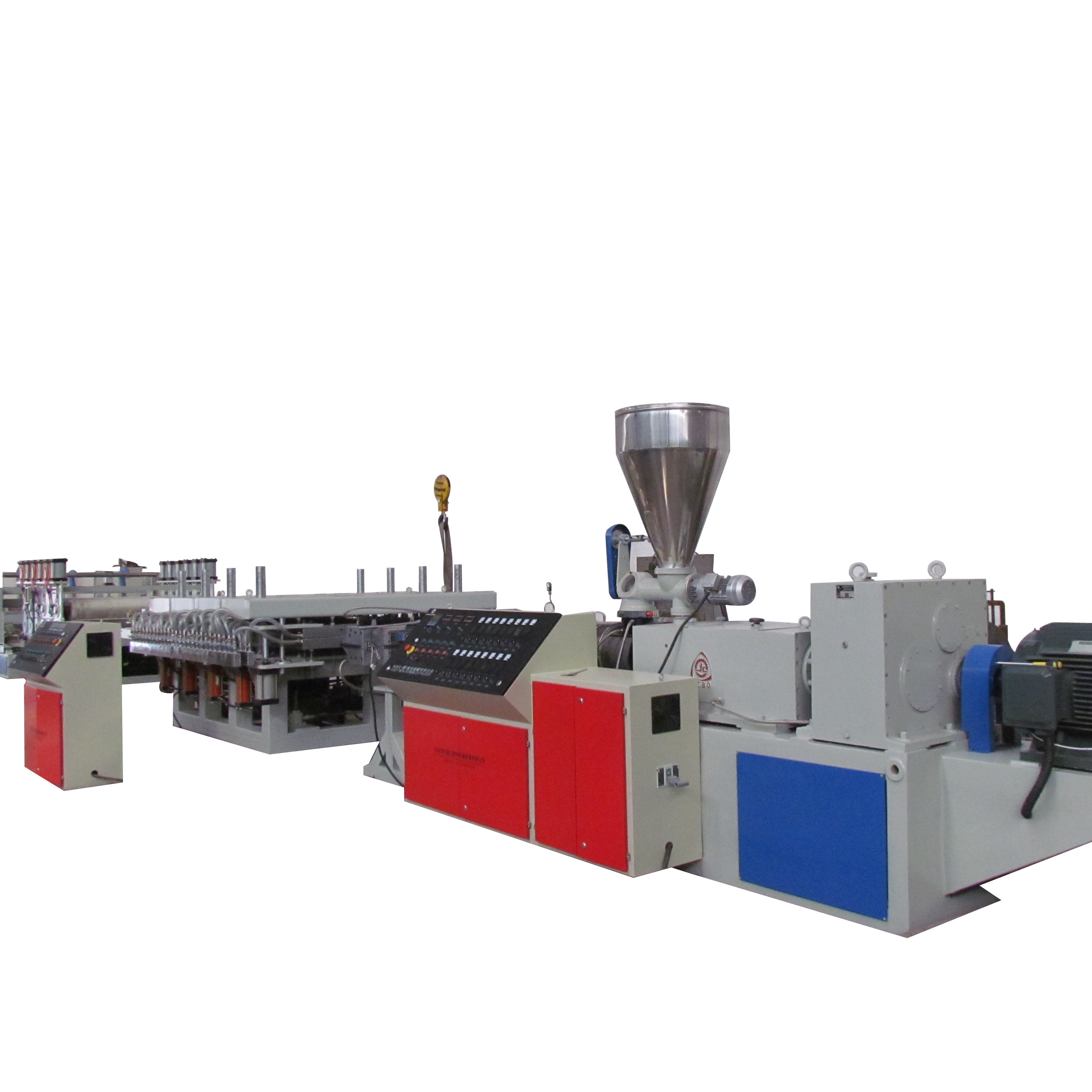

PVC WPC Foam Board Production Machine

Features and application

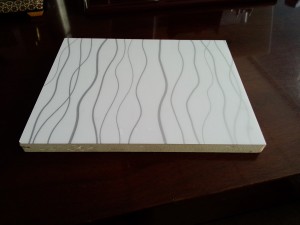

WPC foam board has such characteristic as sound separation sound absorption.

the material is incombustible,it is safe for use

all series of products have property of moisture proof,mildew proof,water resistance,its vibration resistant effect is good

all series of products have property of weathering proof, its luster may remain forever,it is not easy to be ageing.

this product is light, storage ,transport. Construction are rather convenient.

this product can be worked with normal tools for wooden material .

drilling ,sewing,nail,planing,bonding can be conducted like wooden material

it is suitable for thermal shaping, thermal bending and fold processing

it can be welded.it can also be bonded with other pvc material

the surface of this product is smooth,it can be printed (clean the surface before printing)

main technical parameter of PVC WPC foam board production machine

| Model | Extruder | Width | Thickness | Capacity |

| BDX-1220 | SJSZ80/156 | 1220mm | 25mm | 350kg |

| BDX-1830 | SJSZ92/188 | 1830mm | 25mm | 800kg |